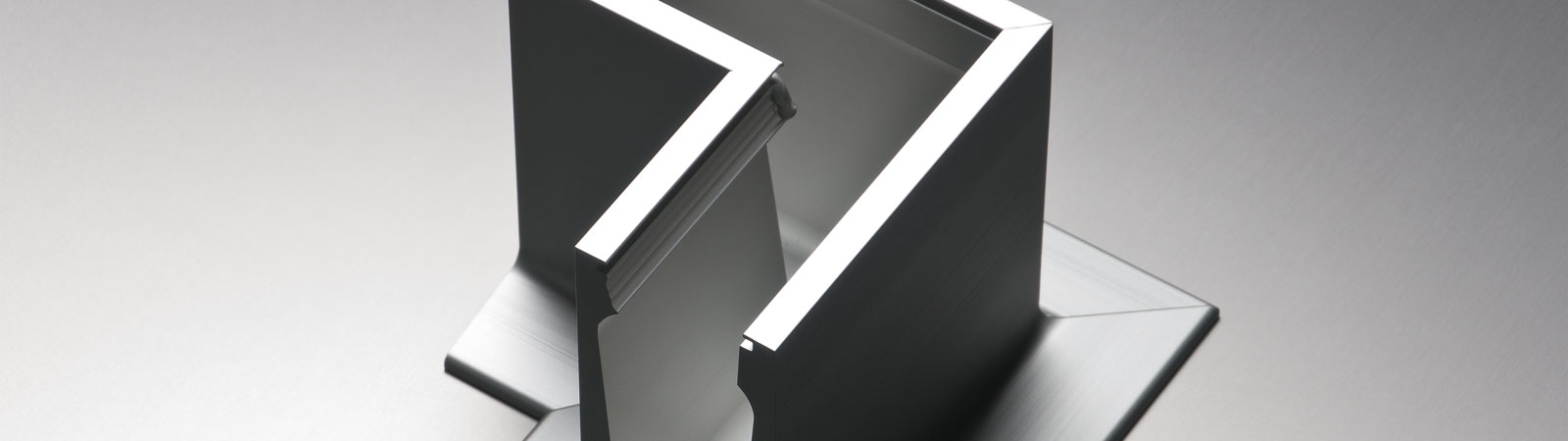

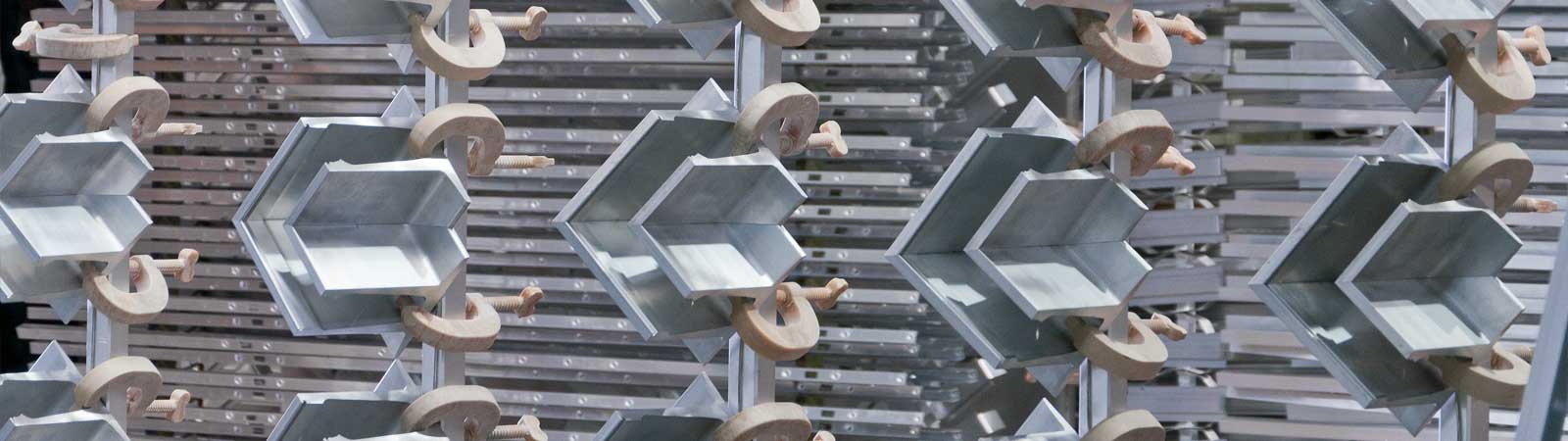

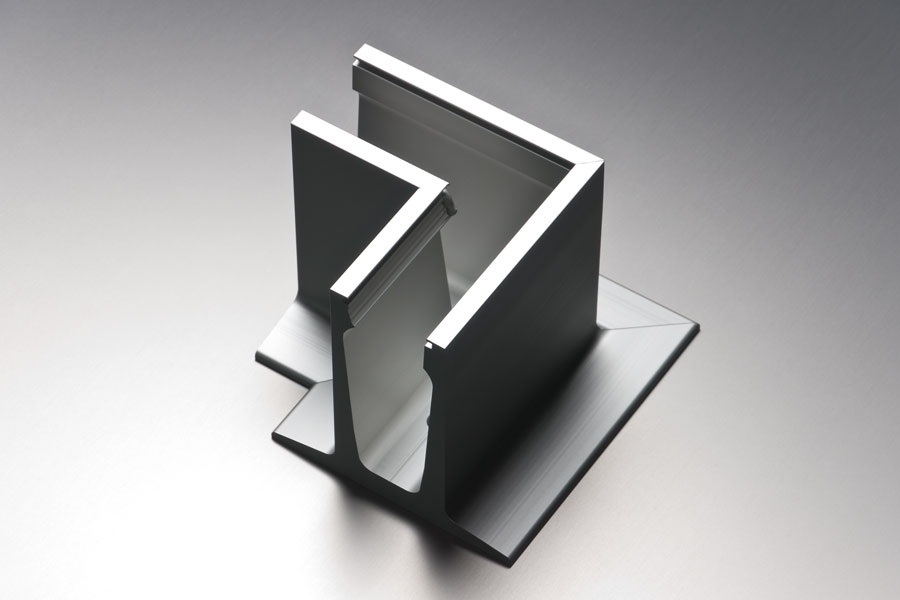

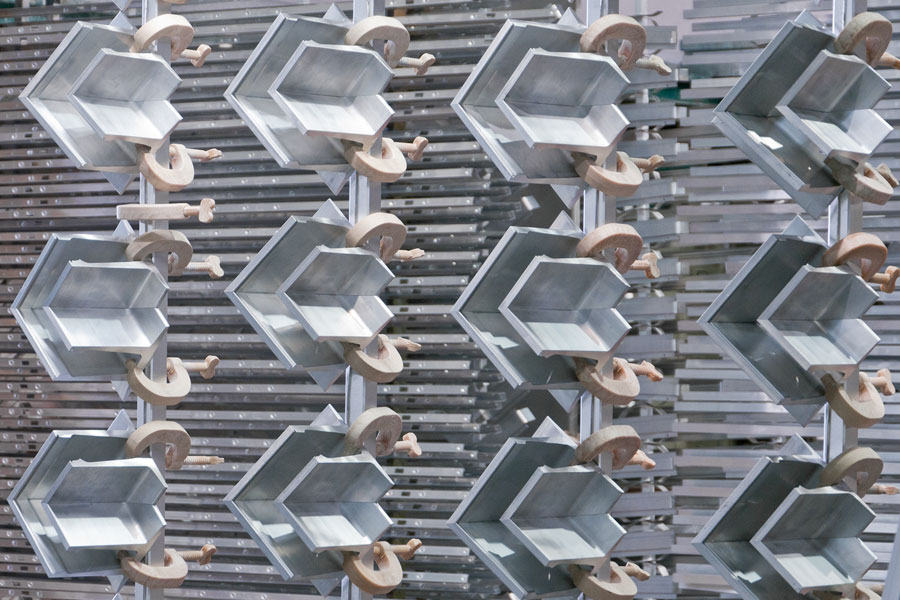

Glas railing corner

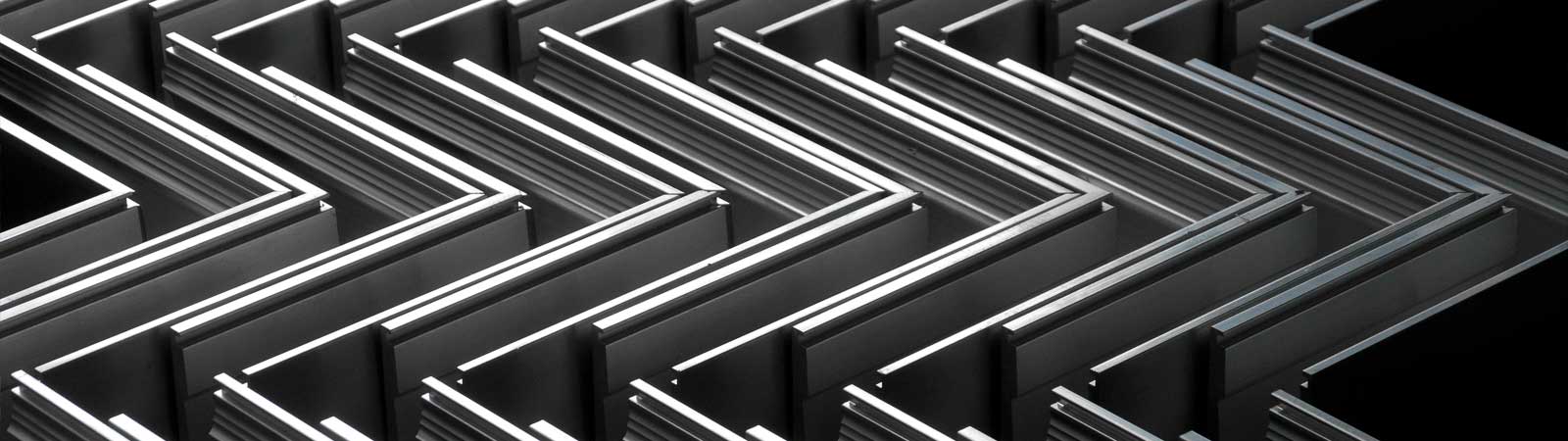

ALUTECTA produces the complete glas railing corner elements for an architectural railing system. Form, colour + function. The components are customised with a bevel cut, machined holes and notches either in a serial production or commissioned for architectural projects. Depending on the desired colour the profiles can be grinded before sawing and anodisation. The massive design, high precision and accuracy in combination with the decorative anodised surface demand high production standards in manufacturing. The complete production of the elements at one location from one supplier allows a economical effective realisation, reduces mistakes, delivery times and costs.

Production steps

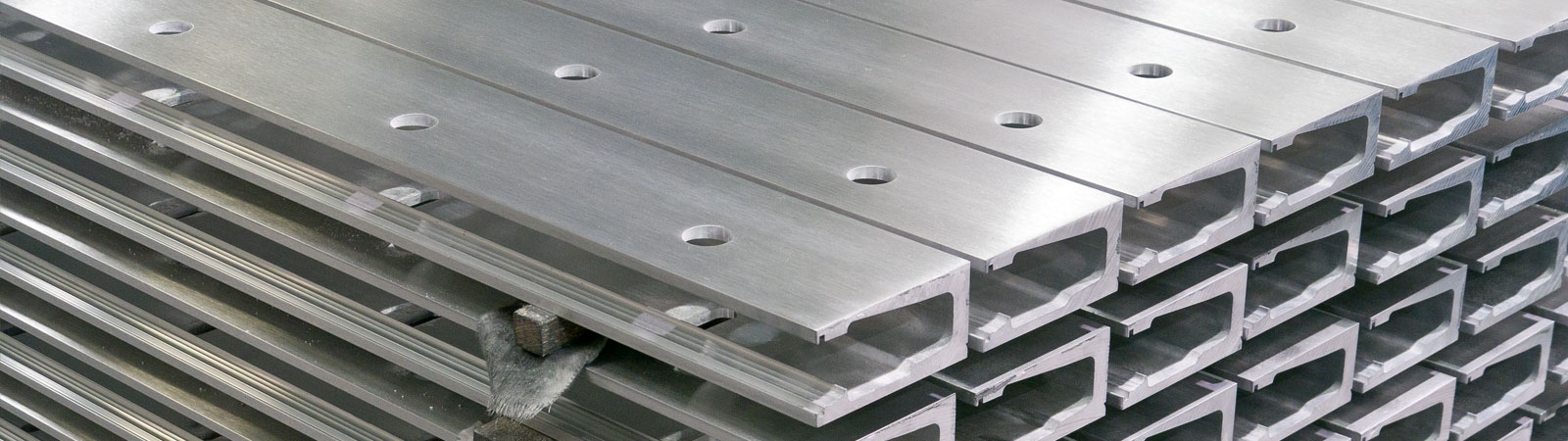

- Grinding aluminium profiles

- Sawing - with precise measurements and bevel cut

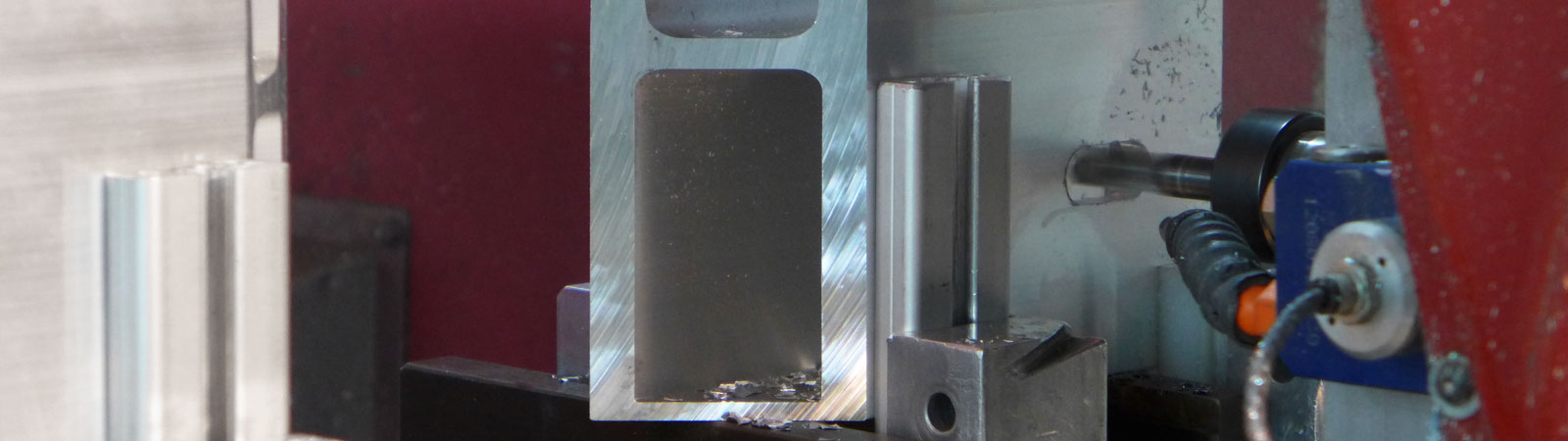

- Machining CNC-Milling

- Deburr

- Connecting the elements - welding

- Grinding the welding points

- Surface - Anodisation z.B. ALANOX®