ANODISING - surface & design

Anodising

The anodic oxidation process transforms the metal surface into a dense and very hard oxide layer which is firmly bonded to the base material. It provides effective protection against mechanical influences and offers both weathering and corrosion resistance. The oxide layer being translucent the metal gloss of the material is maintained. It is grown by passing a direct current through an electrolytic solution and may be dyed by use of various processes. The coloured dyes are thus being incorporated in this layer and remain protected from any environmental stress. Anodized aluminium may easily be regained for new further processing and offers thus a sustainable and environmentally sound type of surface finishing.

The anodic oxidation process transforms the metal surface into a dense and very hard oxide layer which is firmly bonded to the base material. It provides effective protection against mechanical influences and offers both weathering and corrosion resistance. The oxide layer being translucent the metal gloss of the material is maintained. It is grown by passing a direct current through an electrolytic solution and may be dyed by use of various processes. The coloured dyes are thus being incorporated in this layer and remain protected from any environmental stress. Anodized aluminium may easily be regained for new further processing and offers thus a sustainable and environmentally sound type of surface finishing.

Technical Information

Colour & Structure

The oxide layer produced in the anodization process (Eloxal) maintains transparent. It keeps the natural aluminium colour. There are two ways to change the look of the anodised material:

The oxide layer produced in the anodization process (Eloxal) maintains transparent. It keeps the natural aluminium colour. There are two ways to change the look of the anodised material:

A. Oxide layers can be coloured with the Colour-two-step- or with the SANDALOR®process.

B. The aluminium surface can be pretreated with a chemical and a mechanical process. This treatment changes the structure and the reflection properties of the surface.Both options can be combined to a great variety of design possibilities that all maintain the metallic look of aluminium.

Anodising Colour & Structure Information

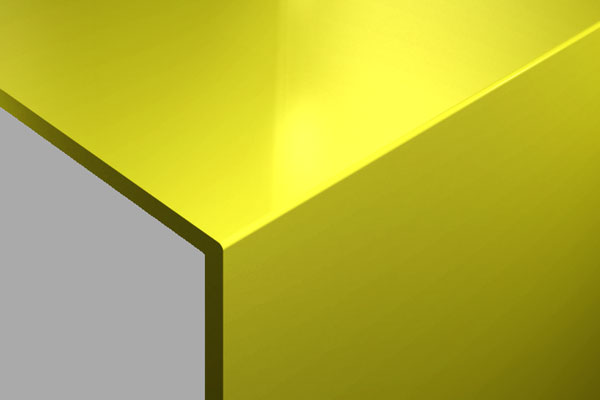

SANDALOR®

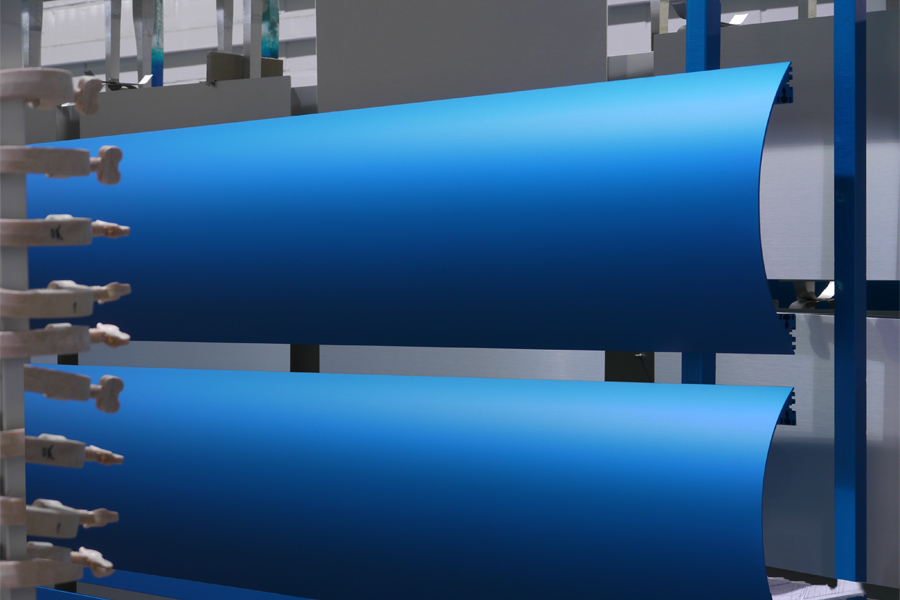

The SANDALOR® - technology extends the available colour range to yellow, gold, red, blue and turquoise. By combination with the Colour-two-stage process, SANDALOR® colours can be obtained in various brightness levels. The play of colours between e.g. the basic colour red and red-black is vibrant with bright metallic effects. The lightfastness of the colourants we use ranges beyond value 8 on the ISO-Blue-Scale and is thus suitable for any kind of application, even for outside applications in architecture.

SANDALOR® Product info page

ALANOX®

Our anodised surface ALANOX® provides a stainless steel look to aluminium. A specific repeated grinding in combination with a particular colouring result in this stainless steel effect which is much demanded especially for architectural applications. But stainless steel is used increasingly in further fields as well (furniture e.g.). For metal workers the advantage of aluminium with stainless steel effect consists in the fact that he is used to aluminium processing and that there are hardly any restrictions for construction. Material costs are lower as compared to stainless steel, there are no problems with finger prints left on the components, ALANOX® opens up new application fields for aluminium. The layer thickness is of at least 20 µm.

ALANOX® Product info page

GRANODAL®

GRANODAL® is a newly developed method by ALUTECTA, used to colour anodised aluminium surfaces in variations of grey. The resulting surface provides an unmatched look and feel. Its metallic characteristics are fully preserved with this purely inorganic colouring. The surface arising shows a subtle shimmer with varying light impressions and countless rather neutral variations of grey, no blue or green tints. The colouring is UV- and weather resistant, not fading and does not display stains when exposed to weathering. These properties come along with the noted quality features of anodising: scratch-proof, durable and corrosion resistant. GRANODAL® therefore especially shows its qualities when applied outside, it guarantees the durability of the finished product and is a warrant for creative design in numerous sectors.

GRANODAL® Product info page

Anodised-Engraving plates

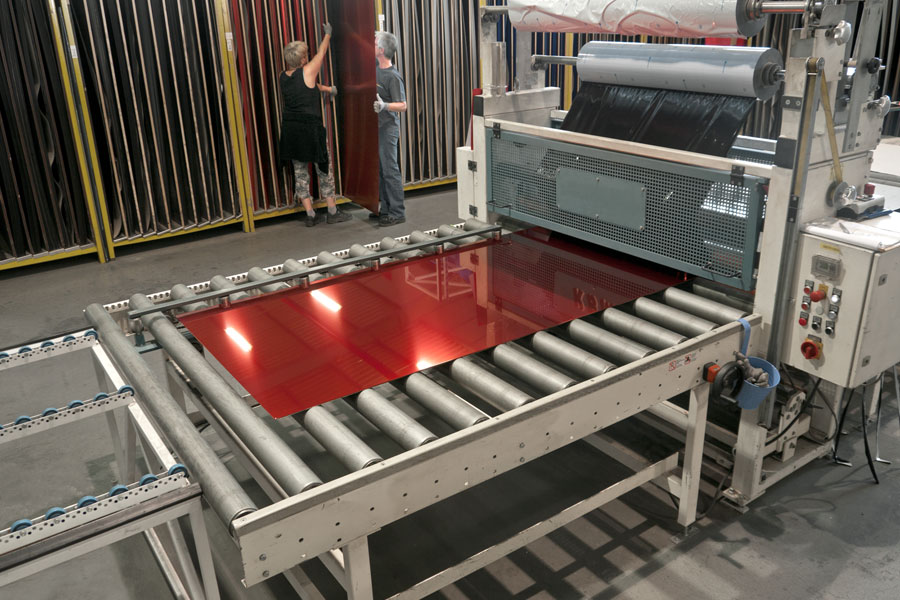

For years Alutecta has been a strong partner of the engraving industry. We produce engraving-sheets in our factory with specialy high quality standards. After the surface treatment the sheets are covered with protection foil and packed ready for transport. A great variety of colours and sheet thicknesses are available from stock.

Engraving plates info page

Anodisation - Eloxal

Both terms stand for the same process. Anodising is the internationally used term. Eloxal, the term used in Germany, means electrolytic oxidation of aluminium.

The anodic oxidation process transforms the metal surface into a dense and very hard oxide layer which is firmly bonded to the base material. It provides effective protection against mechanical influences and offers both weathering and corrosion resistance. The oxide layer being translucent the metal gloss of the material is maintained. It is grown by passing a direct current through an electrolytic solution and may be dyed by use of various processes. The coloured dyes are thus being incorporated in this layer and remain protected from any environmental stress.

Anodized aluminium may easily be regained for new further processing and offers thus a sustainable and environmentally sound type of surface finishing.

Potential component size:

length 7000 mm x width 800 mm x height 2000 mm

Anodising and Colour

The oxide layer produced in the anodization process (Eloxal) maintains transparent. It keeps the natural aluminium colour. There are two ways to change the look of the anodised material:

1. Oxide layers can be coloured. Here you can find an overview of the colour possibilities

Aluminium

nature

GRANODAL®

grey

Aluminium

Gold

Colour /

Bronce

Sandalor®

Yellow

Sandalor®

Gold

Sandalor®

Red

Sandalor®

Blue

Sandalor®

Turquoise

2.

The aluminium surface can be pretreated with a chemical and a mechanical process. This treatment changes the structure and the reflection properties of the surface.

Both options can be combined to a great variety of design possibilities that all maintain the metallic look of aluminium.

The following pictures show the combination of the S100-0 colour and the different pretreatments E0-E6 and the resulting optical effect.

E1 S100-0

Coarser or finer chatter marks can be achieved by grinding, anodising and sealing.

E2 S100-0

Brushed, anodised and sealed surfaces remain visible.

E5 S100-0

Grinding and polishing, leaves a glossy surface.

E6 S100-0

The chemical pretreatment produces a matt, rough surface.

Pretreatment E0-E6

Anodically obtained oxide layers are translucent. The major part of the light falling onto an anodised surface is not reflected on the surface of the oxide layer itself but on the oxide layer/metal interface. This is why its metallic appearance may be maintained during anodising. Pretreatment is thus of vital importance as for the visual effect of anodised aluminium. We distinguish between two processes: chemical pretreatement by alkaline etching in which case a matt surface is produced, and mechanical pretreatment through brushing, grinding, polishing etc.. This is how various surface effects can be achieved (gloss, grind or matting).

The various pretreatment methods are marked by their respective abbreviations E0 to E6 according to DIN 17611.

E0

No pretreatment, anodised and sealed.

Die or chafe marks and other surface defects remain visible. Appropriate for hidden surfaces, e.g. to back shadow gaps, push rods etc.

E1

Grinded, anodised and sealed.

Relatively uniform surface with duller appearance: small die marks or scratches are removed (no surface grinding). Depending on the size of the abrasive grain, coarser or finer chatter marks remain visible.

E2

Brushed, anodised and sealed.

Uniform, bright surface. Brushing is visible. Die marks, scratches etc are only partly removed. Easy to clean, high self-cleaning effect on outdoor applications. Most common mechanical pretreatment.

E3

Polished, anodised and sealed.

Glossy surfaces: die marks, scratches etc are only partly removed. Preferred indoor application. Low maintenance.

E4

Grinded and brushed, anodised and sealed.

Uniform, bright surface: die or chafe marks and other surface defects – especially hidden corrosion phenomena – that may show for E0 or E6 are removed, (no surface grinding). Low maintenance.

E5

Grinded and polished, anodised and sealed.

Even, glossy surface: die or chafe marks and other surface defects – especially hidden corrosion phenomena – that may show for E0 or E6 are removed, (no surface grinding).

E6

Chemical pretreatment, anodised and sealed.

Matt, rough surface: die or chafe marks and other surface defects are partly removed. Material-induced surface defects may not always be avoided. Possible corrosion phenomena affecting the aesthetic appearance and which could not or difficultly be identified prior to etching, may show as a result of this treatment.

Please ask for specimen or samples!

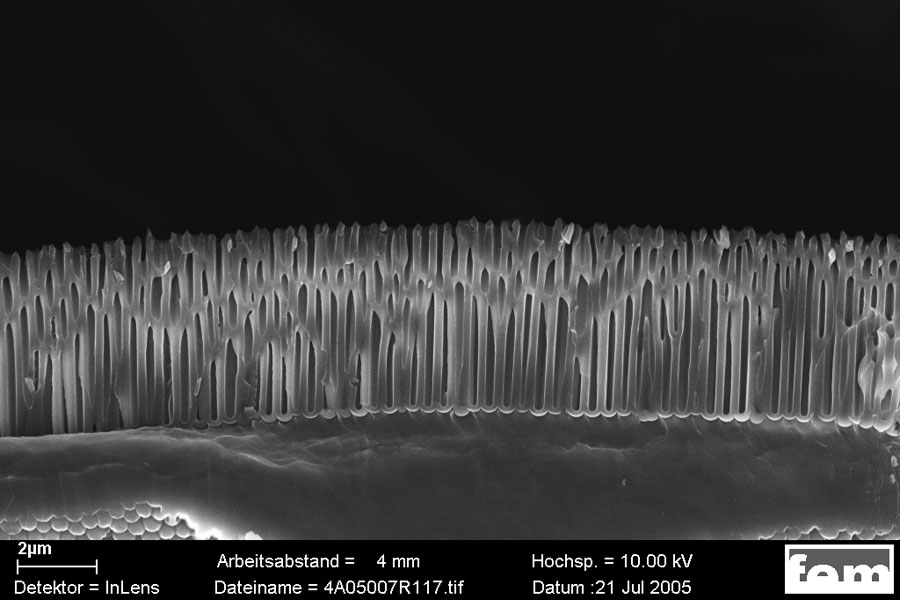

The process

Under natural conditions aluminium produces an oxide film protecting the underlying material. This process is optimized under technical conditions in an anodising bath, aluminium being the only material allowing anodising. The natural oxide film of an aluminium component is merely 0.1 – 0.5 µm thick, unaesthetic and has a low hardness. However, a technically generated anodised layer offers very specific properties as for its layer thickness and texture, density and optical homogeneity.

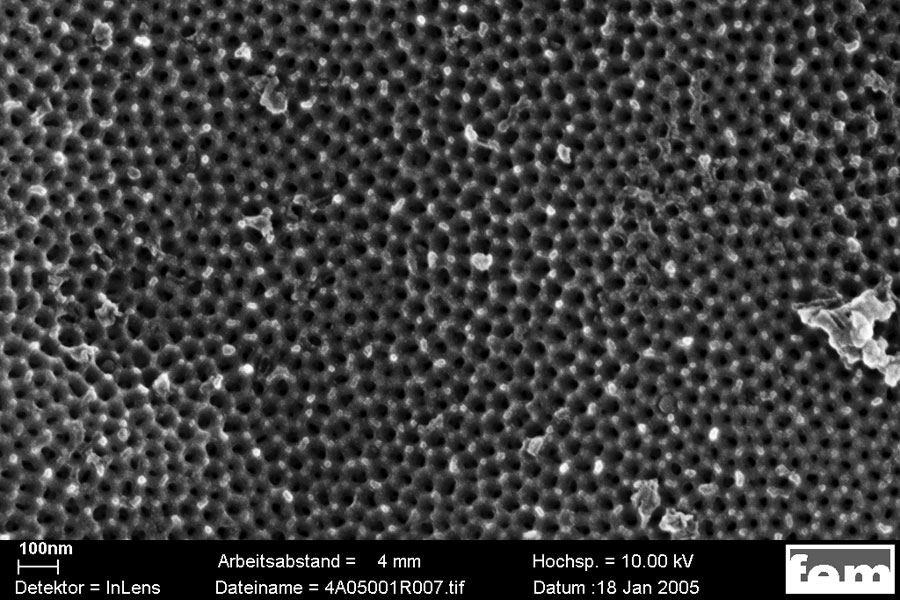

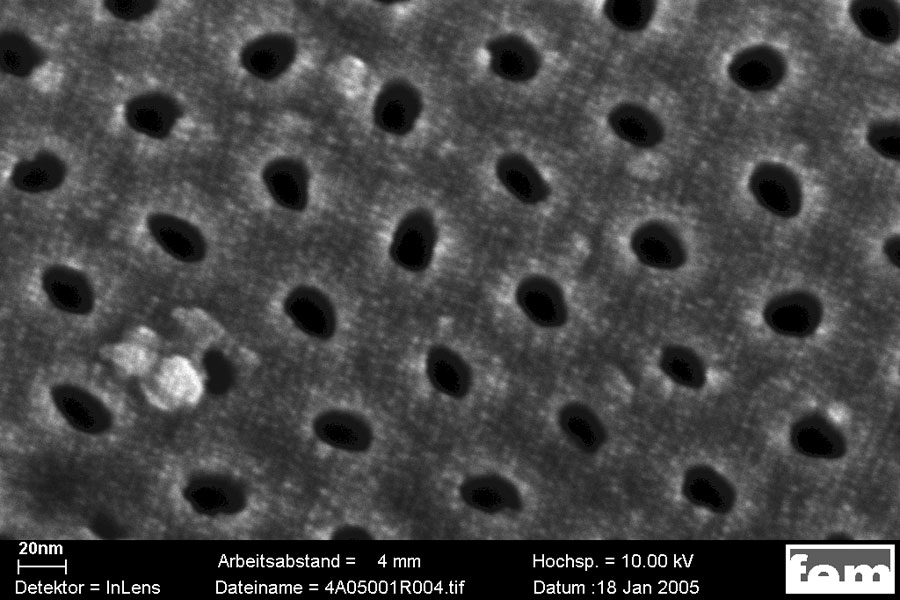

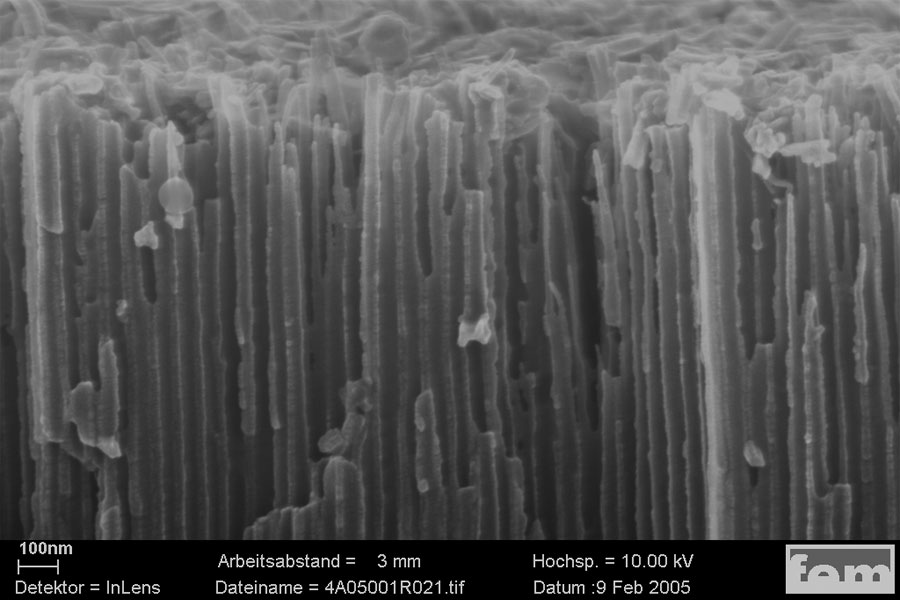

(Arbeitsabstand = working distance / Hochspannung = high voltage)

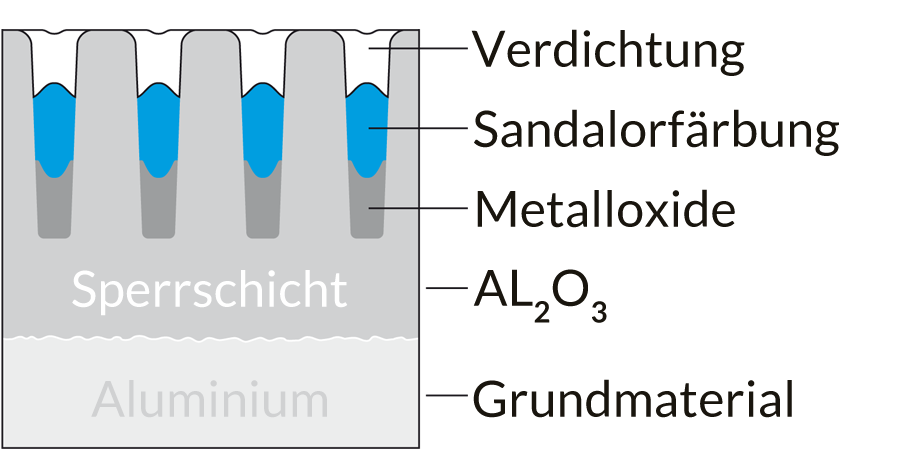

The anodised coating is grown in an electrolytic solution, e.g. in sulfuric acid. In an anodising bath direct current is passed through an electrolytic solution, the aluminium component to be anodised serving as anode. The cathodes are placed on the bath's edges. The requested anodised Al2O3 coating is generated in an extremely complex electrochemical reaction. A rather thin but closed barrier layer forms in a first step. Nanopores emerge as the layer grows (see illustration below).

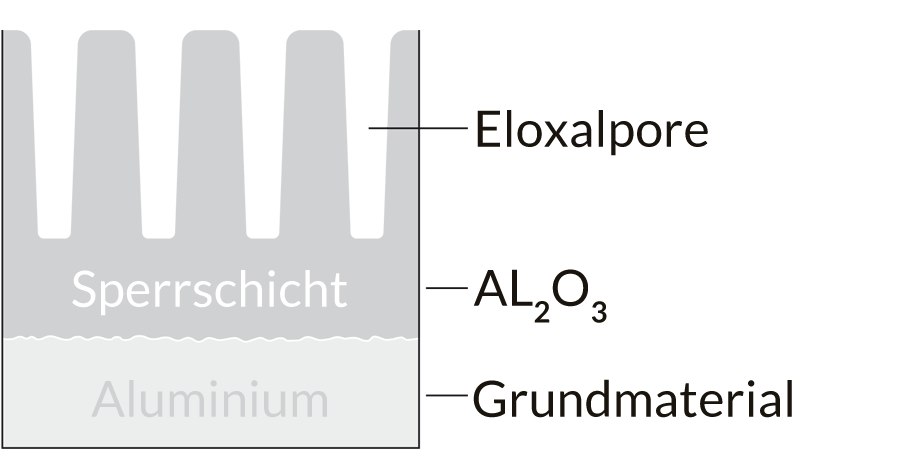

Aluminium surface with empty anodic pore:

(Eloxal = anodic coating / Sperrschicht = barrier layer / Grundmaterial = basic material / Eloxalpore = anodic pore)

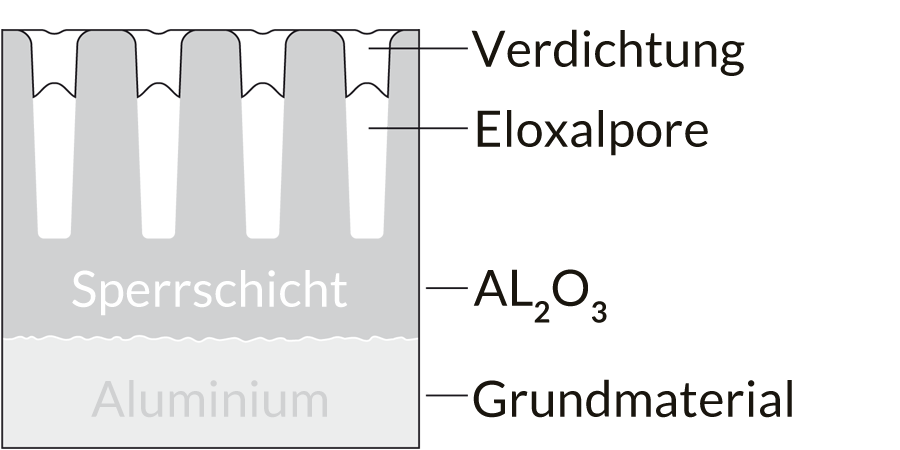

Energy released during this process is recovered for the purpose of heating the manufacturing units. The parameters chosen during the anodising process allow to determine properties such as density and pore size of the anodic coating. The open-pored surface obtained in the anodising bath offers a unique possibility to fill these pores with colours (gold, brown, black, blue, red, yellow, turquoise etc.). Hence the dye does not only cover the surface but rather fills the anodised pore and is completely protected (see also colour anodising). The last procedural step consists in the sealing of the pores. Under the effect of demineralized water at a temperature of 100°C emerges the translucent alumina hydrate. It forms inside the pore and constitutes a hermetical sealing, i.e. an additional protection of the colour (see illustration below).

Aluminium surface with anodic pore and sealing (see above, Verdichtung = sealing)

Sealing is extremely important with regard to corrosion resistance and durability of the aluminium surface.

Please ask for specimen or samples!

Colour anodisation

Two-step process for the electrolytic colouring of anodised aluminium

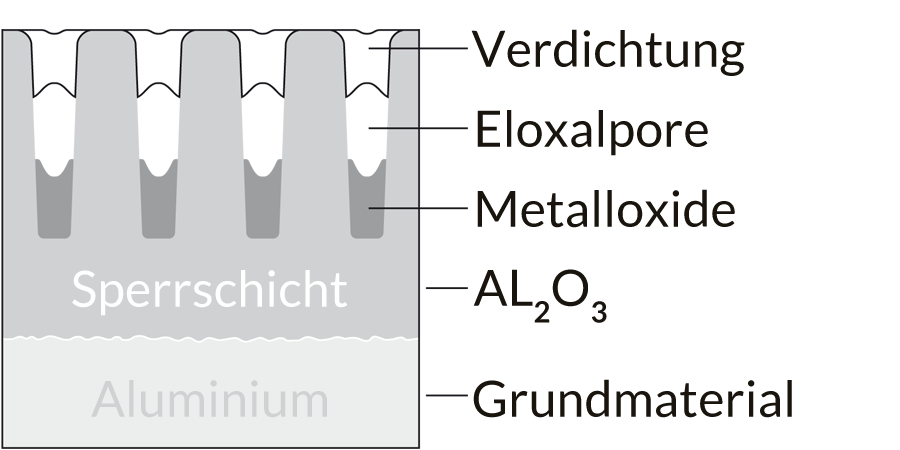

The translucent anodised layer produced by anodic oxidation corresponds to the natural colour of aluminium (EV 1). In a second step and subsequent to this colourless oxidation the layer may be dyed electrolytically by means of a metal salt solution. The metal oxides that have been embedded in the open-pored anodised layer produce lightfast shades, thus offering a colour lightness that may be graded from light beige and bronze to black (C11 - C14). The colour effect does not occur on the anodised layer's surface but rather on its pore bottom, completely protected from any environmental influence (see Illustration below).

Aluminium surface with anodic pore, dye and sealing

After the dye has been enclosed the pores are sealed. This process is called closing or sealing (see also 'Process'). It always constitutes the final step of the anodising process and is of vital importance as for weathering and corrosion resistance of aluminium.

Overview of the Colour - process colour possibilites

Aluminium

nature

GRANODAL®

Aluminium

Gold

Colour /

Bronce

Stainless stell effect

grey

The  - process

- process

With the combination of the two-step process for the electrolytic colouring of anodised aluminium and the absorption of dyes in a dye bath, numerous shades (yellow, gold, red, blue and turquoise) may be achieved for varying levels of brightness. Whereas electrolytically embedded metal oxides may be found on the pore bottom, adsorptive shades deposit along the pore walls (see Ill.). The lightfastness of the dyes we use exceeds value 8 of the ISO-Blue-Scale. The colour effect is extremely vivid with bright metallic shades.

Potential component size :

length 7000 mm x width 600 mm x height 2000 mm

Please ask for specimen or samples!

Aluminium surface with anodic pore, two-step process for electrolytic colouring, Sandalor colouring and sealing

Sandalor®

yellow

Sandalor®

gold

Sandalor®

red

Sandalor®

blue

Sandalor®

turquoise

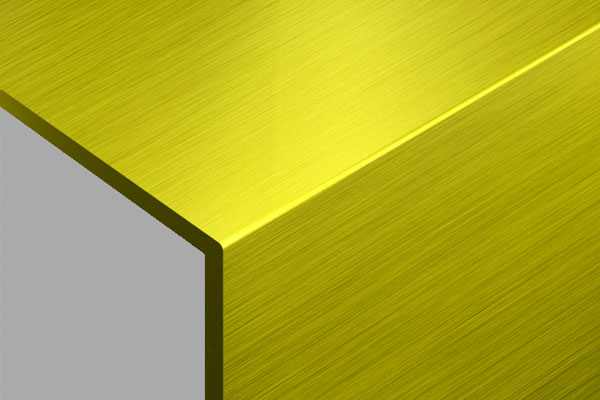

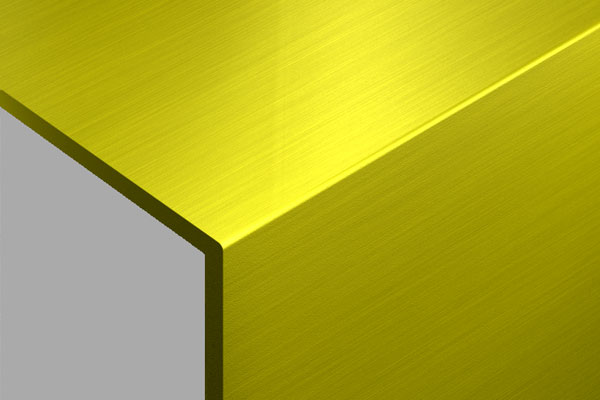

ALANOX®

Our new anodised surface ALANOX® provides a stainless steel look to aluminium. A specific repeated grinding in combination with a particular colouring result in this stainless steel effect which is much demanded especially for architectural applications. But stainless steel is used increasingly in further fields as well (furniture e.g.). For metal workers the advantage of aluminium with stainless steel effect consists in the fact that he is used to aluminium processing and that there are hardly any restrictions for construction. Material costs are lower as compared to stainless steel, there are no problems with finger prints left on the components, ALANOX® opens up new application fields for aluminium. The layer thickness is of at least 20 µm.

Besides profiles it is also possible to process sheet metal blanks with the following maximum dimensions: length 7000 mm, width 400 mm.

Potential component size:

Profiles: length 7000 mm x width 400 mm x height 2000 mm

Sheets: length 7000 mm x width 400 mm x height 2000 mm

GRANODAL®

ALUTECTA presents GRANODAL® - Grey anodised Aluminium

Grey anodised aluminium or GRANODAL® is a new aluminium surface developed by ALUTECTA. If offers unique possibilities for inside and outside applications in architecture and product design. 'With its subtle shimmering appearance, varying light impressions and countless variations of grey, the surface provides an unmatched look and feel to aluminium.

Unlike any colouring or coating technique, the new lightfast surface is produced by embedding metal components in the anodised material using a technical process specially refined and advanced by ALUTECTA for the grey GRANODAL® surface. This ensures that the finished product is still made of pure non-corrosive anodised metal and has an outstanding, durable and highly weather and scratch resistant surface, ready for use in any kind of application. As the reaction of metal components is always slightly different, the results of the process in the production of GRANODAL® are never exactly the same, an effect that enhances the lively and individual character of the material and adds to the uniqueness of the product.

GRANODAL® Advantages for design and production :

- lightfast

- combinable with pretreatment E0-E6

- UV- and weather resistant

- Durable, scratch resistant

- Pure non-corrosive anodised metal

- no colouring or coating

- Lively, characteristic surface for a broad range of products

- exceptional and refined look

- for a great bandwidth of innovative products

Potential component size: length 6500 mm x width 400 mm x height 2000 mm

As the reaction of metal components is always slightly different, the results of the process for the production of GRANODAL® are never exactly the same, an effecta that enhances the individual character of the material and adds to the uniqueness of designs and products.

GRANODAL® is produced in different colour shades C71-C73, completed by the stainless steel effect ALANOX®grey and varied through many possibilities of surface pretreatment with brushing, grinding, chemical pretreatment and polishing.

Please contact our distribution for further information.

Anodization-Engraving quality

For years Alutecta has been a strong partner of the engraving industry. We produce engraving-sheets in our factory with specialy high quality standards. After the surface treatment the sheets are covered with protection foil and packed ready for transport. A great variety of colours and sheet thicknesses are available from stock.

- High quality anodised surface in different colourvariations on aluminium sheets suitable for engraving

- Available from stock in different sheet thickness

- Gloss and Matt surface is possible

- One sided or two sided, (incl. protective foil one sided / two sided)

- Dimensions = 1000x2000mm / 500x1000mm

- Sheet thickness Gloss = 1.0mm, 1.5mm, 2.0mm

- Sheet thickness Matt = 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm

- Sheet thickness stainless steel effect= 1.0mm, 1.5mm, 2.0mm

- Protective foil 75 µm

- Material = AlMg3 GQ + EQ (Matt) / AlMg1 AG1S (Glanz)

- Minimum quantity per colour in 1000*2000mm = one sided 12 units / two sided 6 units

- Minimum quantity per colour in 500*1000mm = one sided 48 units / two sided 24 units

the following standard colours are available directly from stock

Gren (S170-0),

Orange (S130-0),

Red (S140-0),

Blue (S150-0),

Black (C65-1),

Bright bronze (C11),

Medium bronze (C12),

Dark bronze (C13),

Stainless steel effect (ALANOX-G1, only matt, only one sided),

Nature (EV1),

Gold (EV3),

New silver (G1A)

Properties

When exposed to atmospheric influence, untreated aluminium forms a natural oxide layer which usually protects the base material from further corrosion effects. However, this oxide layer is extremely thin (0.1 – 0.5 µm after a few months), unaesthetic and possesses a low hardness. This natural process may be used when optimized technically to obtain a considerably thicker and harder anodised layer, which is highly aesthetic and takes dyes.

Anodized aluminium components combine numerous advantages. Good processability and high stability of the material provide an extremely high formability. The anodised surface stands for high protection and low maintenance. Shades and textures offered provide you a large leeway for surface design and visual effect of the idea you put in aluminium.

This new anodised layer is non-conductive, very hard and takes dyes (see colour anodising). A specific printing process incorporates the colour into the anodised layer in a way to obtain a perfect abrasion-proof print. The anodised layer consisting of Al2O3 is a very thin ceramic coating which is firmly bonded to the aluminium. In the event of the recycling of an aluminium component the oxide layer remains in the melting furnace and can easily be removed.

Technical advice

The following technical advice shall provide you assistance. The numbers listed have been taken from literature, we therefore ask you to please understand that we cannot guarantee for the correctness of these data.

Density |

|

| Aluminiumoxid (Eloxal) | 3,94 kg/dm3 |

| for comparison | |

| Aluminium | 2,7 kg/dm3 |

| Steel | 7,85 kg/dm3 |

| Stainless steel 1.4301 | 7,95 kg/dm3 |

Hardness in HV (Vickers) |

|

| Anodized layer | 250 – 450 HV (Vickers) |

| for comparison | |

| Aluminium | 50 – 70 HV |

| Heat treated steel | 150 – 320 HV |

| Stainless steel 1.4301 | 150 – 200 HV |

| Layer thickness without specification | we anodize approximately 20 µm (0,02 mm) |

Abrasion resistance |

|

| AlMg 1 (EN AW 5005) | 3000 - 5000 Rotations with 1000 g according to Taber |

| AlMgSi 0,5 (EN AW 6060) | 9000 - 12000 Hubs/µm according to Siemens + Halske |

Breakdown voltage |

|

| Anodized layer | 30 V/µm result at 20 µm ca. 600 V |

Thermal conductivity |

|

| AlMg 1 (EN AW 5005) | 160 – 220 W/(m K) |

| for comparison | |

| AlMgSi 0,5 (EN AW 6060) | 200 – 220 W/(m K) |

| Aluminium oxide (Eloxal) | 28 W/(m K) |

| Stainless steel 1.4301 | 15 W/(m K) |

Expansion coefficient |

|

| Anodized layer | 6 x 10-6/K |

| for comparison | |

| Aluminium | 23 x 10-6/K |

| Steel | 11 x 10-6/K |

| Stainless steel 1.4301 | 16 x 10-6/K |

Electric resistance |

|

| Aluminium oxide (Eloxal) | 1 • 1018 Ω mm2/m |

| for comparison | |

| Aluminium | 2,65 • 10-2 Ω mm2/m |

Dielectric constant |

|

| Anodized layer | 5 - 6 |

| for comparison | |

| Glas | 5 - 7 |

Cleaning + maintenance

Stubborn dirt may easily be removed from anodised components thanks to their very hard and durable oxide layer. They are mar-resistant and require low maintenance.

An abrasive basic cleaning as first cleaning is essential in the case of components for outdoor use. Aluminium components, as any other components, are subject to natural pollution when exposed to weathering. To maintain the aesthetic appearance cleaning and maintenance should be performed in accordance with the recommendations of the Gütegemeinschaft für die Reinigung von Metallfassaden e.V. GRM (Quality Association for the Cleaning of Metal Facades GRM).

Repair

Smaller defects and scratches may be concealed by means of specific anodising touch-up applicators respectively anodising sprays that can be ordered from us. Components showing important processing defects or large-scale damages will have to be de-anodised and reprocessed where required.

UniversAL

Cleaning & Protection UniversAL Cleaner To be applied on all powder-coated metal and façade elements with smooth coloured varnish or structured and metallic finishes, as well as on all coated/anodised finishes. Product properties: This universal cleaner is a speciality product for the protection and maintenance of powder-coated and anodised finishes. It contains care components, solvents and preserving agents. In addition, it also protects surfaces from weather effects and environmental pollutants. UniversAL does not contain polishing agents nor silicon compounds or aromatic hydrocarbons.

UniversAL Cleaning & Protection for powder-coated or further coated / anodised aluminium surfaces comes in a set with a 100 ml bottle plus cleaning cloth or in a 500 ml bottle.